No. 8 East Dai Road, Dongcheng, Huangyan District, Taizhou City, Zhejiang Province 1285628684@qq.com

Contact me : 008618267603137

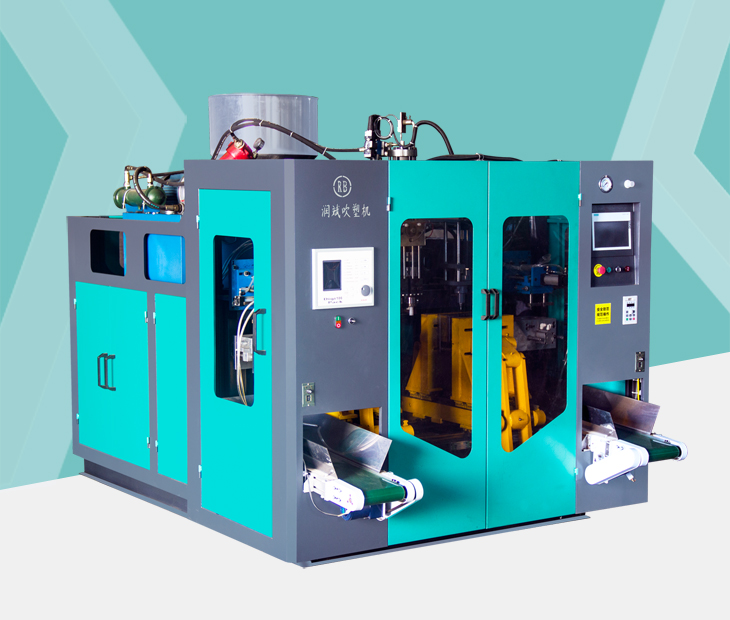

1. This machine is suitable for producing 200ML-10L plastic hollow products. It adopts toggle clamping system with low energy consumption, center clamping, large clamping force, fast speed and more stable operation.

2. Mold opening and closing system: specially designed counterbalanced mold locking mechanism, using high-pressure mold clamping, the force of the locking plate is set at the center of the plate, the clamping force is large, and the open and strong locking plate can be installed even for ultra-wide molds. .

3. Die head system: All are made of 38CrMaALA and other high-quality materials, which are made by precision machining and heat treatment.

4. Hydraulic system: full oil pressure dual proportional hydraulic control, stable and reliable.

5. Automatic flashing device: The spill removal device can accurately cut off the remaining material of the product, and is equipped with a direct push overflow removal device and a rotary knife overflow removal device.

适用于生产12L以下的PE, PP, EVA, ABS,K料、TPU、尼龙等材质的塑料中空制品

Product Advantages: In the design and production process of Runbin hollow blow molding machine, new technology and supporting facilities are adopted, such as: Siemens PLC controller, American Moog wall thickness controller, etc., to further optimize the overall performance of the equipment, expand the application field of the equipment, and ensure The equipment is energy-saving and stable in operation.

Technical advantages: Runbin hollow blow molding machine has an experienced R&D team and an independent processing and manufacturing workshop, which has incomparable advantages in the speed of technology research and development and product updates.

Service advantages:Runbin can provide corresponding one-stop blow molding machine customization solutions according to customer requirements. During the equipment installation process, technicians will be arranged to help with equipment installation and commissioning, including The teaching and training of machine operators, excellent quality, stable performance, and superior cost performance make the company's products not only sell well in the domestic market.

No matter where you use our products, Jinming people will provide you with

professional door-to-door installation services. All installers have passed technical installation training and answered various questions and demands on the spot

.

Runbin Machinery promises a 100% pass rate for all factories. All Runbin Machinery customers can enjoy life-long service, technical support and free consulting services.

Runbin Machinery builds a 24-hour quick response mechanism, the whole machine is guaranteed for 1 year and

The whole process of installation and maintenance will be tracked and returned until you are satisfied.

This machine is fully automatic production, high energy saving, low noise, fast speed, high benefit, safe and reliable, widely used in plastic packaging industries such as toys, food, beverage, medicine, chemical industry, pesticide, washing supplies, etc., for blowing oil bottles, Pesticide bottles, cosmetic bottles, large-diameter bottles, hot-fill bottles, etc. The machine has low investment, quick effect and convenient operation and maintenance. Installation, commissioning, training, perfect quality assurance, and full-service services make you feel at ease when purchasing and using, and it is your ideal choice for purchasing. The machine has single-die double-station, double-die double-station, four-die double-station.

Technical parameters and configuration:

Product parameters

Specification

Die Head

Carriage system

Extruder Unit

Power Unit

Remarks

After with 100 points parison control

1、各机型的加热功率与模头配置有关,因模头配置不同,可能出现加热功率稍有差异的情况。

2、本参数表仅供参考,实际机型参数可能会有所调整。

1. The heating power of each model is related to the configuration of the die head. Due to the different configuration of the die head, there may be a slight difference in heating power.

2. This parameter list is for reference only, and the actual model parameters may be adjusted.