No. 8 East Dai Road, Dongcheng, Huangyan District, Taizhou City, Zhejiang Province 1285628684@qq.com

Contact me : 008618267603137

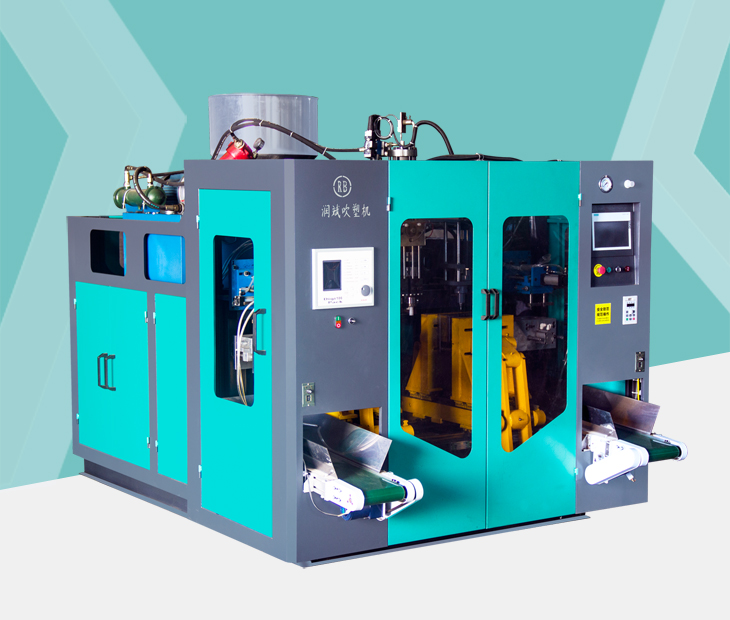

Performance characteristics of the model

1. It is suitable for producing plastic hollow products made of PE, PP, EVA, ABS, K material, TPU, nylon and other materials below 2L.

2. The structure of four guide pillars balanced pull and push rods, the down-loading superhard quenched and tempered guide pillars and the fully open template design can accommodate ultra-long and ultra-wide moulds.

3. You can choose to output products to the side or to the bottom, which is convenient for producing different products.

4. Touch-screen man-machine interface, easy to operate and set.

5. Double pump design: under low pressure, two hydraulic oil pumps supply oil in parallel, and under high pressure, one hydraulic oil pump supplies oil, and the other hydraulic pump unloads. Small power loss, energy saving and low consumption.

6. The double proportional valve controls the flow rate and pressure of the oil circuit, the reversing valve controls the flow direction, the deceleration valve brakes, and the action is smooth and fast;

7. The central force design of the template, clamping The force is evenly distributed;

8. CE standard safety design, focusing on user safety;

9. Japanese inverter adjusts the screw speed to save power and energy;

10 , Automatic lubrication system, reduce equipment maintenance workload.

Product Advantages: In the design and production process of Runbin hollow blow molding machine, new technology and supporting facilities are adopted, such as: Siemens PLC controller, American Moog wall thickness controller, etc., to further optimize the overall performance of the equipment, expand the application field of the equipment, and ensure The equipment is energy-saving and stable in operation.

Technical advantages: Runbin hollow blow molding machine has an experienced R&D team and an independent processing and manufacturing workshop, which has incomparable advantages in the speed of technology research and development and product updates.

Service advantages:Runbin can provide corresponding one-stop blow molding machine customization solutions according to customer requirements. During the equipment installation process, technicians will be arranged to help with equipment installation and commissioning, including The teaching and training of machine operators, excellent quality, stable performance, and superior cost performance make the company's products not only sell well in the domestic market.

No matter where you use our products, Jinming people will provide you with

professional door-to-door installation services. All installers have passed technical installation training and answered various questions and demands on the spot

.

Runbin Machinery promises a 100% pass rate for all factories. All Runbin Machinery customers can enjoy life-long service, technical support and free consulting services.

Runbin Machinery builds a 24-hour quick response mechanism, the whole machine is guaranteed for 1 year and

The whole process of installation and maintenance will be tracked and returned until you are satisfied.

Electric mold shifting blow molding machine: 30% energy saving of the whole machine, 20% increase in production capacity

1. Electric mold shifting is controlled by a servo motor, and the mold can be moved quickly within 1 second , accurate positioning, fast speed, stable operation

2. The horizontal mold shifting structure of the crank arm, the mold shifting stroke can be adjusted, and can adapt to a variety of center distance moulds, the movement is stable and not easy to be damaged, and the service life is long

3. Needle lowering, mold opening and closing are controlled by hydraulic servo motors, pressure and flow are adjustable, precise and energy-saving

4. The machine head uses a double-ring eight-channel shunt shuttle, which discharges evenly and efficiently Smooth, fast color change

5. The equipment is equipped with a lifting platform and cold knife cutting, energy-saving and safe

6. Automatic joint lubrication and automatic recovery of waste oil in the oil guide tank to reduce product pollution

p>

7. Japan's Mitsubishi PLC, intelligent module temperature control, accurate temperature, less than the set temperature, the equipment does not run, not easy to damage the screw and machine head

8. The overall aluminum tile temperature control of the screw , fast heating, long heat preservation time, energy saving and energy saving

9. Each temperature zone of the screw is equipped with an independent leakage short-circuit protector, which is easy to troubleshoot

10. With air-conditioning circulation, the Internal hot air is removed and cold compressed air enters, saving cooling time and increasing production capacity

Technical parameters and configuration: