No. 8 East Dai Road, Dongcheng, Huangyan District, Taizhou City, Zhejiang Province 1285628684@qq.com

Contact me : 008618267603137

润斌吹塑机械、以创新求进取、以诚信求根本、以质量求发展、以服务求生存的理念打造吹塑界的知名品牌而努力着

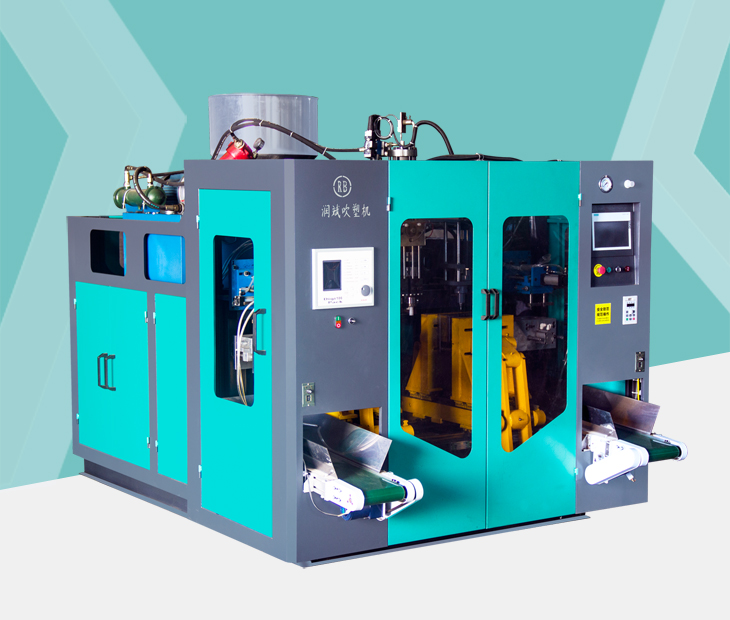

全自动中空吹塑机采用连续式模头设计,台湾威纶触摸屏显示,日本三菱PLC控制。 全中/英文显示人机对话,直接明了,操作简单方便。各项配件均采用知名品牌配置,设计合理,机器外观简洁大方,内在性能稳定,能充分满足你对生产塑料制品的各项要求。

技术特点:我们采用螺旋芯棒组合系统,具有高度适应性,多段结构达7层。多层共挤出机头采用流变设计,每一层中具有良好的圆周分布,层组合原料分布均匀,能加工范围较宽的塑料原料。

1:直线导轨支撑单模架,经有限元分析设计,确保锁模力充足,不涨模。

2:超大开模行程,中心锁模,锁模力均衡,不变形。

3:高精度无熔合线储料式模头,换颜色方便,配伺服壁厚控制系统,提高产品质量,降低生产成本。

4:可选配多功能下吹机构,自动取产品机械手等多种辅助装置,实现生产过程高度自动化。

5:全系机型配备安全保护光栅,确保生产过程安全无事故。

Product Advantages: In the design and production process of Runbin hollow blow molding machine, new technology and supporting facilities are adopted, such as: Siemens PLC controller, American Moog wall thickness controller, etc., to further optimize the overall performance of the equipment, expand the application field of the equipment, and ensure The equipment is energy-saving and stable in operation.

Technical advantages: Runbin hollow blow molding machine has an experienced R&D team and an independent processing and manufacturing workshop, which has incomparable advantages in the speed of technology research and development and product updates.

Service advantages:Runbin can provide corresponding one-stop blow molding machine customization solutions according to customer requirements. During the equipment installation process, technicians will be arranged to help with equipment installation and commissioning, including The teaching and training of machine operators, excellent quality, stable performance, and superior cost performance make the company's products not only sell well in the domestic market.

No matter where you use our products, Jinming people will provide you with

professional door-to-door installation services. All installers have passed technical installation training and answered various questions and demands on the spot

.

Runbin Machinery promises a 100% pass rate for all factories. All Runbin Machinery customers can enjoy life-long service, technical support and free consulting services.

Runbin Machinery builds a 24-hour quick response mechanism, the whole machine is guaranteed for 1 year and

The whole process of installation and maintenance will be tracked and returned until you are satisfied.

Basic Specifications

Opening and Closing System

动力

extrusion system

模头